Selecting the right stainless steel finish for your application is very important. You are probably looking for a long lifespan, corrosion resistance and low maintenance needs. The right finishing is the way to guarantee that不锈钢will behave as expected.

但是,该过程可能会令人困惑。有不同的标准为每种不锈钢表面饰面提供自己的指定。一些制造商甚至创建了内部标准,以指定其产品的表面饰面。

To make it simpler for you, we recommend focusing on the most recognised standards around the world. For example, both DIN and ASTM standards are very common. Therefore, we are using these as our examples.

分裂的laser cutting service for stainless steels优惠instant quotes onlinewith a variety of surface finish possibilities available for selection.

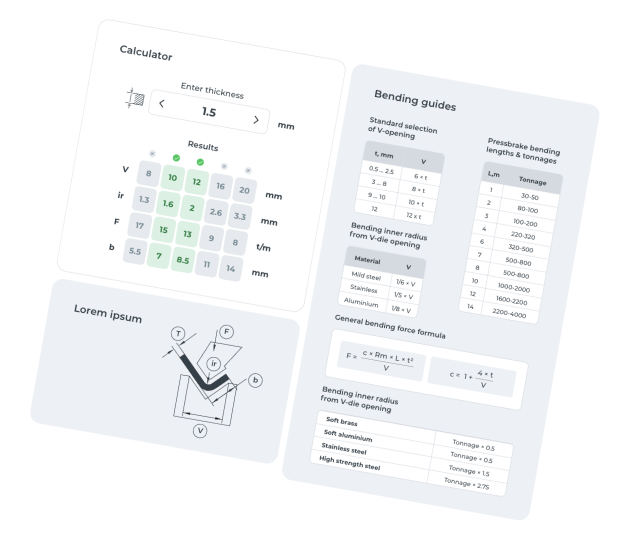

根据DIN和ASTM等效物,不锈钢饰面

首先,以表格格式比较DIN和ASTM饰面。这为您提供了使用这两个标准的可能性的很好概述。我们将在文章稍后详细介绍每个完成的详细信息。

磨坊完成

| DIN名称 | ASTM Equivalent | Description |

|---|---|---|

| 1d | No. 1 | Hot rolled, heat treated andpickled。粗糙的表面,但没有刻度尺度。 |

| 2b | No. 2B | 冷卷,热处理,腌制和皮肤经过。光滑的表面。 |

| 2d | No. 2D | 冷卷,热处理和腌制。光滑的表面。 |

| 2H | tr | 工作硬化。寒冷为更高的力量而努力。明亮的表面。 |

| 2r | ba | Cold rolled, bright annealed and skin passed. Smooth, bright and reflective surface. |

| 2q | - | Cold rolled, hardened and tempered. Scale free surface. |

Polished and Brushed Finishes

| DIN名称 | ASTM Equivalent | Description |

|---|---|---|

| 1G-2G | No. 3 | Ground. Grade of grit or surface roughness can be specified. Unidirectional texture, not very reflective. |

| 1J-2J | No. 4 | Brushed or dull polished. Grade of brush, polishing belt or surface roughness can be specified. Unidirectional texture, not very reflective. |

| 1k-2k | No. 6 | 缎子抛光。J型饰面的其他特定要求,可在海洋和外部建筑应用中具有足够的耐腐蚀性。 |

| 1p-2p | No. 7-8 | 明亮的抛光。可以指定过程或表面粗糙度。非方向饰面,具有高度图像清晰度的反射性。 |

Patterned & Coloured Finishes

| DIN名称 | ASTM Equivalent | Finish | Description |

|---|---|---|---|

| 2F | No. 2D | 图案表面 | 冷卷,热处理,皮肤经过粗糙的卷。明亮的退火或退火和腌制。均匀的非反射马特表面。 |

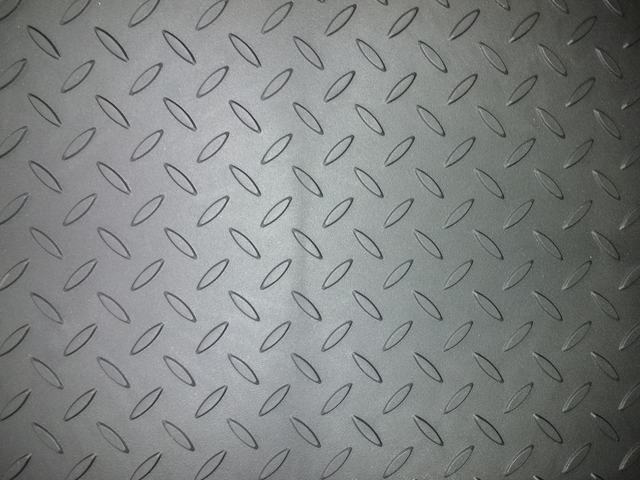

| 1m | - | 图案表面 | 同意设计。One side is flat. Plates used on floors. |

| 2m | - | 图案表面 | 同意设计。One side is flat. Fine texture mainly used for architectural applications. |

| 2W | - | 图案表面 | 同意设计。双方都具有波纹质地,用于增加强度和/或用于美学。 |

| 2L | - | Coloured Finish | 颜色在协议。颜色obtained by a chemical process. |

| 1S-2S | - | 表面涂层 | 通常涂有锡,铝或钛。 |

磨坊完成for Stainless Steel

Mill finish is the basic supply condition for stainless steels, no matter whether they are cold or hot rolled. However, most of these steels require further finishing processes to meet the requirements of certain applications.

这是对不锈钢的深入描述,该钢根据上表落入该组。

一维不锈钢饰面 - 热卷,退火和腌制

在钢中将钢滚入磨坊后,然后将其穿过一种称为退火的热处理。Annealing consists of heating the steel and letting it cool down slowly to remove internal stress and reduce hardness. This makes it more ductile and workable.

在退火过程之后,一维不锈钢已准备好完成最后一步,以实现指定的饰面 - 腌制。此过程包括用酸清洁表面以去除鳞片。在先前的过程中形成秤,热滚动和退火。

Get your metal fabrication quote in seconds

Quote in seconds

交货时间很短

分裂交付

最终的表面稍微粗糙,反射率非常低,典型的平均水平粗糙度(RA)between4…7微米。

1d不锈钢is sometimes used as the starting point for polished finishes. However, common applications of this stainless steel surface finish involve non-decorative purposes. Thus, the visual appearance is not always relevant. Some examples include:

- Unexposed support systems

- 结构应用

- 空气加热器

- Furnace conveyors

- 热交换器

- 油燃烧器零件

2dSurface Finish – Cold Rolled, Annealed & Pickled

因为这种钢是冷滚动而不是热滚动的,表面饰面更精致。退火和腌制工艺以与1D不锈钢相似的方式改善其特性。在这种情况下,必须进行腌制,因为进行退火以消除压力并减少因冷滚动而导致的硬度。

表面饰面的反射性哑光外观低,典型的平均粗糙度值范围从0。4to 1.0 micrometers。

Similarly to the 1D surface finish, the 2D can be the starting point for polished finishes. It can also be used for some industrial and engineering needs with less critical aesthetics. Common applications for 2D stainless steels are:

- Railcar parts

- 汽车排气系统

- Builders’ hardware

- Chemical equipment

- 电范围零件

- 石锚

- Roof drainage systems

- 石化设备

2B饰面 - 冷卷,退火,腌制和皮肤通过

Another cold rolled stainless steel where the process is similar to producing 2D. The difference is that there is an extra step in producing 2B stainless steel surface. That step is rolling it one final time with highly polished rolls known as bright rolls.

获得的典型平均粗糙度是0.1和0.5微米。因此,结果是光滑的,略微到中度反射的表面,并具有良好的平坦控制。

由于其暗淡的灰色和反射性的外观不是很高,因此仅当均匀度不需要时才用于体系结构。2B不锈钢饰面的常见应用包括但不限于:

- 烘焙设备

- Refrigeration

- Food processing application

- Tanks and vessels

- vacuum drum dryers

- 太阳能收集器面板

- Pharmaceutical equipment

2rFinish – Cold Rolled, Bright Annealed & Skin Passed

Again, there is only a small difference with previously described surface finishes. In this case, we have the bright annealing process added. It consists of annealing the steel under oxygen-free conditions to protect it from oxidation and scaling.

这resulting stainless steel finish is capable of reflecting clear images. It is very smooth and less likely to harbour airborne contaminants and moisture compared to any other mill finishes. This easy-to-clean finish has a typicalRa between 0.05…0.1 micrometers。

2R,也称为BA不锈钢,通常用于国内应用。对于反射很重要但其精度却不重要的应用程序也不是。一些例子是:

- 我nner part of washing machines and dishwashers

- Commercial refrigerators

- Food processing equipment

- Builders’ hardware

- Surgical instruments

- 高速公路卡车拖车

- Road mirrors

2HFinish – Cold Rolled & Work Hardened

This one is a little different to the rest of the mill finishes. Here, the metal is cold worked after the cold rolling process in order to obtain improved strength. The hardening is done by means of temper rolling on polished rolls. 6 different levels of strength are available depending on the产量强度,拉伸强度和伸长率。

结果是相当平稳的反射效果。2H饰面的表面粗糙度由制造商定义,这取决于脾气滚动过程。

这most common applications of the 2H stainless steel finish include:

- 汽车应用程序

- Chains

- 机器和仪器

- Press plates

- Surgical instruments

- 我mplants

- 冲压零件

2qFinish – Cold Rolled, Hardened & Tempered

2Q不锈钢饰面与2H饰面非常相似,因为它是冷滚动并随后硬化的。不同之处在于,2Q在保护气氛中被加固并在热处理后降低。因此,它专门用于martensitic steels这是对这些治疗的反应。

2Q饰面的表面平滑且无标度。同样,表面粗糙度是由制造商定义的。

Being very similar to the 2H, the applications are almost the same, including but not limited to:

- 汽车应用程序

- 机器和仪器

- Surgical instruments

机械抛光和拉丝不锈钢饰面

在选择不锈钢时,有一些建议适用。作为起点,请选择最接近所需结果的磨机饰面。这样,可以最大程度地减少其他过程的数量。

但是,通过机械抛光和刷表面可以实现标准饰面。这意味着将通过使用磨料材料来处理表面,这些磨料有效地将钢表面切成理想的程度。

这resulting surface finish for mechanically polished and brushed stainless steels will depend on different aspects. Those include the original surface (初始点),抛光带和刷子的类型和纹理以及所使用的抛光过程的性质。

Here are the details of the stainless steel finishes that fall into this group based on the table above.

1G – 2G Stainless Steel Finish

这种饰面是通过研磨获得的。1G指的是热卷初始点而2G是指冷滚。

由于所使用的过程,结果饰面提供了相当粗糙的单向表面,反射率较低。表面粗糙度可以由制造商定义,并根据要求与客户同意。大多数制造商定义了Ra up to 1 micrometer。

Still, it depends on the material and roughness of the grinding belts. The 180 grit and 240 grit ones are the most common.

Generally, common applications of this finish are:

- Brewery equipment

- Food processing equipment

- Kitchen equipment

- 科学设备

- 我ndoor architectural applications

1J – 2J Stainless Steel Finish

这起点for these finishes are the same as the previous ones. But now the hot rolled or cold rolled steels are processed with polishing belts or brushes. Thus achieving a more refined surface compared to the 1G-2G surfaces.

但是,结果仍然是单向的,不是很好的反射性。制造商可以指定刷子,抛光带或表面粗糙度的等级。典型的平均水平粗糙度在0.2…1.0微米之间, although most manufacturers prefer to stay around0.4…0.6微米for the 1J – 2J finishes.

1J - 2J不锈钢饰面的一些最常见的应用是:

- 建筑墙板

- 饮料设备

- 公路坦克拖车

- Furniture

- 电梯门和室内装饰

- 水槽

- Sterilisers

1K - 2K完成

这初始点is usually hot rolled or cold rolled steel, annealed, pickled and skin passed. Then, finer grit belts and brushes give the steel a satin polish.

这1K – 2K finish provides a smooth reflective surface with an averageroughness of 0.5 micrometers or lower,一些制造商的速度低至0.06微米。

这finish is highly corrosion resistant. Also, you can define additional requirements for adequate corrosion resistance for marine and external architectural applications.

例如,常见应用程序包括:

- 大气性能至关重要的外部建筑应用

- 沿海环境应用

- 装饰应用

1P - 2P不锈钢表面

这相同的起点随着1K - 2K的结束。在这种情况下,最后一个过程是用软布拖把和特殊抛光化合物抛光和抛光。这有助于实现明亮的抛光效果。

这1P – 2P are non-directional, ultra-smooth and highly reflective finishes with a high degree of image clarity in the reflection.这些不锈钢的典型RA值低于0.1微米。

被认为是耐腐蚀性的最佳表面,1p - 2p饰面具有许多应用。例如,这些应用适用于表面表面:

- Column covers

- 装饰装饰

- External wall panels

- 镜子

- 反射器

- Signage

不锈钢的图案饰面

产生图案不锈钢饰面包括用图案卷来按下或滚动。这些操作导致有效的薄板。结果,这允许较薄的覆层,随后可能的节省成本和总体体重减轻。

该图案可以在一侧或两侧施加,以实现2面图案不锈钢。

这se are the designations that fall into this group.

2F完成

它通常以2B或2R磨机的效果开始。因此,常见的处理涉及冷滚动,heat treatment和皮肤在粗糙的卷中传递。有时,可以执行明亮的退火或退火和腌制。

结果是低取代的不锈钢饰面。它是薄板两侧的均匀的哑光表面。根据要求定义并商定表面粗糙度。

此表面表面最常见的应用包括:

- 汽车排气系统

- Builders’ hardware

- Chemical equipment

- Roofing

1M - 2M不锈钢表面

这se are the most common 1-sided patterned stainless steels. One side is flat and different textures can be achieved.

这design for the pattern is agreed with the manufacturer and mainly depends on the specific application. However, the main idea of the textures is to use them where surfaces are susceptible to accidental knocks and scratches. Therefore, damages are less likely to be noticed.

Also, building entrances use this stainless steel surface finish to avoid accidents caused by slippery floor.

Popular applications are:

- 建筑入口

- Lift cages

- 机场航站楼

2WStainless Steel Finish

这些是两面图案的不锈钢,在其中滚动或按下图案。该过程使用男性和女性卷和死亡。

同意时定义了模式设计。两侧表面的结果是波纹质地。随后,它增加了强度,但也提供了美学价值。

这applications are the same as the previous finishes, but with the difference that both sides may be visible.

不锈钢的彩色饰面

这些饰面具有不锈钢表面惰性铬层的性质的优势。该层为材料提供了耐腐蚀的性能。

另外,铬层很容易通过化学过程颜色,然后通过电解过程硬化。这些方法达到了所谓的电解色饰面。

如有必要,这些不锈钢饰面也可以图案化。

2LStainless Steel Finish

This is the designation for all coloured finishes. Colours are agreed between the manufacturer and the customer. A wide range of possibilities exists.

这main applications involve mainly decorative or ornamental applications. Sometimes the coloured finish is also used to match with other materials in complex designs.