对不锈钢的需求每年增加5%。2019年,其全球产量达到了超过5200万吨。

At present, a wide number of industries utilise stainless steel. Aside from traditional and marine constructions, household appliances are also experiencing a rise in usage.

While stainless steel is more expensive than软钢, its excellent properties lead to increased service life and reduced cycle cost. So the larger upfront costs pay off in the longer run.

This article will take a closer look at this metal and what makes it so popular in different industries.

什么是不锈钢?

我们知道钢是铁和碳的合金,最大碳含量为2.1%。圣ainless steels are a group of steels that are resistant to corrosion through the addition of alloying elements.

The term stainless steel is used to describe a family of about 200 alloys of steel with remarkable heat and corrosion resistance properties. The carbon percentage can range from 0.03% to 1.2%.

它的显着特征是铬的大量。不锈钢至少含有10.5%的铬,可改善其耐腐蚀性和强度。

合金中的铬在暴露于空气时会在氧化时产生一个被动层。该层是防止进一步腐蚀的盾牌,从本质上讲使合金防锈。这种机制允许在正常工作条件下长期保留一尘不染的外观。

Benefits of Stainless Steel

圣ainless steel has been used with phenomenal success in various industries for over 70 years. More applications are being discovered with every passing year as its advantages become more widely identified.

With an increase in demand, production has increased making it more affordable than ever. Increased demand results in availability in standard as well as non-standard sizes. Also, a wide range of不锈钢饰面is available for choosing.

除了抛光的饰面外,还提供各种图案和彩色表面。这使得找到适合您需求的选择。

圣ainless steel is also 100 per cent recyclable. In fact, half of all stainless steel production is from scrap metal. This makes it a relatively eco-friendly material.

Use-Cases

不锈钢是一种用途广泛的材料。在同时需要钢的性质和耐腐蚀性的情况下,这是优选的。

它的首次用途是餐具,但由于其耐腐蚀性。接下来,它进入了化学工业。今天,我们几乎到处都可以看到不锈钢。

用例因行业而异。例如,用途包括为手表制作微小的零件。同时,具有一定表面饰面的大面板可能覆盖整个建筑物。

A few industries that use stainless steel extensively:

- Food and catering

- Chemicals and pharmaceuticals

- Medical equipment manufacturing

- 建筑和建筑

- Home appliances

- Offshore and shipbuilding

- Automotive manufacturing

- 能源和工业

Types of Stainless Steel

根据金属有望承受的环境,可用的不锈钢等级和表面表面都有许多。根据微观结构,它们可以分为四个主要类别。

奥氏体不锈钢

奥氏体不锈钢has austenite as the primary microstructure. Austenite is a solid solution of iron and carbon that comes into existence above the critical temperature of 723°C. This family of stainless steels displays high toughness and impressive resistance to elevated temperatures.

70 per cent of all stainless steel is austenitic. It contains at least 16% chromium and 6% nickel.

Austenitic stabilisers are elements that are added to prompt the formation of austenite microstructure. This stainless steel grade is anon-magnetic metaland unable to be hardened byheat treatment. Corrosion resistance can be modified depending on the service environment.

Get your metal fabrication quote in seconds

Quote in seconds

Short lead times

Delivery by Fractory

Ferritic stainless steel

铁质钢通常只有铬作为合金元素。铬含量范围为10.5至18%。它们具有平均耐腐蚀性和较差的制造特性。热处理方法也不有助于加强金属。

They generally have better engineering abilities than austenitic grades. Unlike austenitic grades, they are magnetic. They also have good resistance to stress corrosion, resulting in lowercorrosive material wear.

Duplex stainless steel

Duplex is a mixture of austenitic and ferritic stainless steel. Thus, it has the properties of both its constituents. It has high chromium and low nickel concentration. With high tensile strength and good weldability, duplex stainless steels offer unique advantages.

It shows good resistance to stress corrosion but not as much as ferritic grades. It is tougher than ferritic grades but lower than that of austenitic grades.

Martensitic stainless steel

This type of stainless steel consists of high carbon and lower chromium content. Like ferritic grades, it is magnetic. It does display poor weldability compared to other grades but it has higher hardenability and can be heat treated to improve properties.

Martensitic stainless steel will have lower corrosion resistance when compared with austenitic and ferritic grades with the same chromium and alloy content.

Precipitation hardening stainless steels

该亚组提供了奥氏体和马氏体特性的组合。通过添加一个或多个元素,例如铝,钼,niobium,钛和铜来实现硬化。

It is capable of developing high tensile strength through heat treatment. It contains chromium and nickel as alloying elements. These grades are used in high-speed applications such as turbine blades.

Grades of Stainless Steel

There are hundreds of grades of stainless steel in the market today. Choosing the right one for your application is important as their properties can be quite different from each other.

The AISI (American Iron and Steel Institute) system for naming stainless steel is still used by the industry. The numbering system uses three-digit numbers starting with 2, 3 or 4.

200 series

This series is used for austenitic grades that contain manganese. These chromium manganese steels have a low nickel content (below 5 per cent).

200 series find use in:

- Washing machines

- Cutlery

- 食品和饮料设备

- Automotive industry

- In-doors equipment, etc.

300系列

This series is used to name austenitic stainless steels with carbon, nickel, and molybdenum as alloying elements. The addition of molybdenum improves corrosion resistance in acidic environments while nickel improves ductility.

AISI 304 and 316are the most common grades in this series. AISI 304 is also commonly known as 18/8 steel as it contains 18% chromium and 8% nickel.

300系列stainless steel applications include:

- Food & beverage industry

- Automotive industry

- 圣ructural for critical environments

- 医疗仪器

- Jewellery, etc.

400 series

Ferritic and martensitic alloys form this series of stainless steel. These grades are available for heat treating. Providing a good combination of strength and high wear resistance. The corrosion-resistance properties are lower than 300 series, though.

Applications for 400 series include:

- Agricultural equipment

- Motor shafts

- Gas turbine parts, etc.

SAE等级

The SAE system of numbering uses a 1-letter + 5-digit UNS number code to designate stainless steel. The common AISI grade 304 has S30400 as its SAE designation. While most grades have a designation, newly developed exclusive grades may be named by their owners and not have any SAE code.

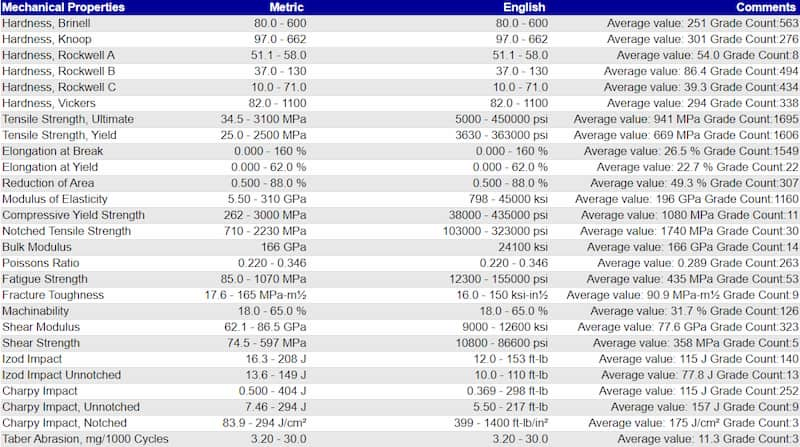

圣ainless Steel Mechanical Properties

If you are unsure what the discussed properties below mean, you can check ouroverview of material properties查看每个人的更长解释。

Yield strength

Depending on the grade, stainless may exhibit high strength and low elongation or low strength and high elongation properties. They compare very well to carbon steels when it comes to yield strength.

圣rength at high temperatures

圣ainless steel performs comparatively better than other carbon steels at higher temperatures. It shows better fire resistance due to its high strength retention factor at elevated temperatures (above 500°C). It also has better stiffness retention factor than carbon steel above 300°C.

Tensile strength

到那个时刻tensile strength,不锈钢优于铝,黄铜和碳钢等材料。

在降水硬化和马氏体等级中看到最高的拉伸强度。这些等级的拉伸强度是无处不在的304和316年级的两倍。尤其是双链钢的强度/延展性比。

Cryogenic resistance

Some stainless steel grades are extremely adept at handling a wider range of temperatures. Austenitic steels display exceptional toughness and increased tensile strength at sub-zero temperatures. This widens the scope of their usage considerably opening up new avenues for modern applications.

另一方面,铁氧体,马氏菌和降水硬化等级不如低温温度不如它们的韧性下降。

延性

The ductility of different stainless steel grades can be significantly different. Some grades have high ductility allowing the use of strenuous deep drawing processes.

较高的工作硬化率

This property refers to a metal’s ability to increase its strength through cold working processes. Stainless steels can be annealed and cold worked to manipulate its strength to the desired level.

This means that the same grade can be used in multiple applications by varying its strength. For example, the same grade may be used as a spring or a bendable wire by annealing and cold working.

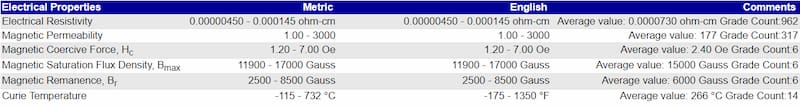

Electric conductivity and magnetism

As all metals, stainless steel conducts electricity. However, this conductivity is extremely low as in the case of all steels.

In industries where hygiene standards are high or the electrical appliance may be subjected to corrosive or humid environments, stainless steel enclosures are used for protection.

奥氏体不锈钢非磁性,豪ver, cold working can be used to induce magnetic properties in some grades. All the other types display magnetic properties.

圣ainless Steel Chemical Properties

Chemical properties are what make this material special and give it its uniqueness.

高氧化耐药性

This distinguishing property of stainless steel is responsible for its many unique applications in the industry. High oxidation resistance is a result of chromium in stainless steel. The percentage of chromium can go up to 26% in some grades.

Other metals may be protected with coatings and anti-corrosion paints but once it wears off, the corrosion begins. In the case of stainless steel, any removal of the natural coating of chromium oxide due to surface damage is followed by the formation of a new coat on the exposed surface that prevents corrosion deterioration.

生物学惰性

不锈钢在生物学上是惰性的,使其成为医疗设备(例如手术工具,创伤螺钉和板)的逻辑选择。该特性还使其成为餐具产品和厨房用具的理想金属。

Resistance to acids, bases and organic materials

不锈钢对多种化合物具有抗性。它耐酸,碱和有机化合物。对酸的耐药性在不同等级方面有所不同。有些等级可以抵抗高浓度的酸,而其他等级可能仅对低浓度具有抵抗力。

Similar non-reactivity is observed with basic compounds and organic compounds. This makes stainless steel a highly suitable material for use in chemical industries for storage, handling and other processes.

不锈钢还可以轻松抵抗水分,盐,硫,二氧化碳和氯化物化合物。与大多数其他金属相比,这有助于它在几个恶劣的环境中生存更长的时间。

Other Properties

重要特性不仅限于机械和化学。下面的其他列表中还有其他方便的各种应用程序。

Recyclability

As mentioned before, recycling stainless steel for making new products is possible. This reduces the strain on the environment for our steel needs by requiring fewer raw materials as well as reducing waste formation.

Its non-biodegradable nature also prevents it from contaminating resources as it does not break down and seep into soil or water reservoirs.

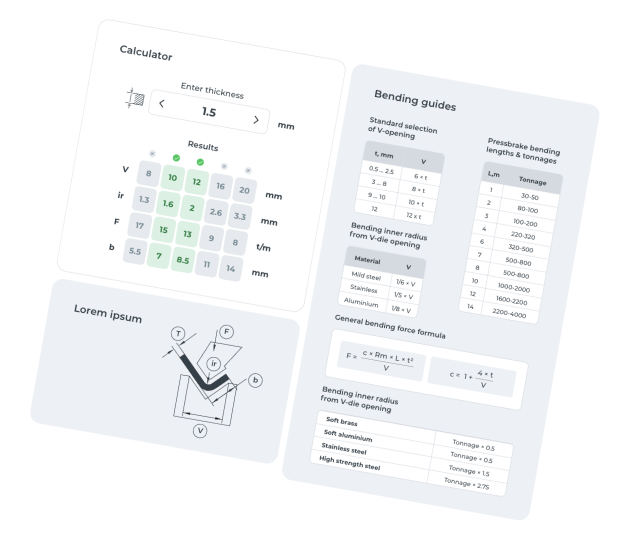

Easy to work with

圣ainless steel is highly machinable and workable permitting a designer to create complex shapes and products.圣ainless steel laser cutting,CNC machining services弯曲等无需任何特殊设备就可以使用。

Cleanability

圣ainless steel products are easy to clean with household non-toxic products such as detergent, soaps or cleaning liquids. This keeps them looking new for a long time increasing the service life.

This ultimately reduces wastage and makes the initial relatively expensive purchase worth it in the long run.

Aesthetic appeal

圣ainless steel products have high luster making it an ideal choice for exposed surfaces. It comes in a wide各种饰面from bright to matt. It may be brushed, engraved, embossed, and tinted for effect.

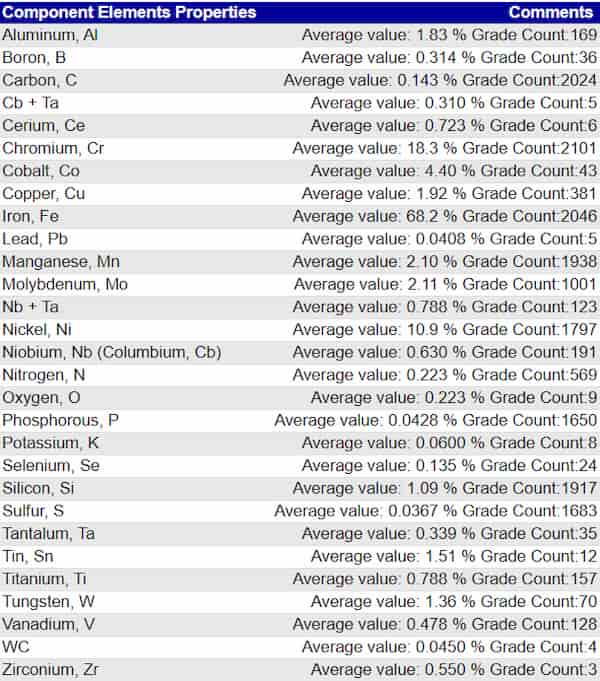

合金元素

当涉及不锈钢时,有很多等级可供选择。根据添加的合金元素的不同,这些属性可能会有很大变化。这取决于应用程序选择最合适的具有成本效益的选项的要求。

Let’s see what alloying elements may be added and how they affect the final product.

Chromium

铬合金元素定义的污渍less steel. It gives the steel its property of being ‘stainless’. The passive layer of chromium oxide along with the protection of the surface also blocks oxygen diffusion into the metal saving the metal’s internal structure from corrosion.

Chromium oxide ions are also similar in size to steel molecules resulting in a strong bond between the two. This enables the oxide ions to remain strongly attached to the surface under normal working conditions.

A minimum of 10.5 per cent is necessary for a steel to be “stainless”. However, adding even more chromium is common for an increased corrosion resistance.

Chromium also acts as a ferrite stabiliser causing the formation of the ferrite microstructure in the alloy.

Nickel

Nickel is added to further improve corrosion resistance. It is also an austenite stabiliser, prompting the formation of austenite.

Adding 8-9% of nickel obtains a fully austenitic structure which provides excellent welding properties. Further increasing the nickel percentage brings about better properties for workability and corrosion resistance.

铜

铜also acts as an austenite stabiliser and improves the property of corrosion resistance and work-hardening.

Adding it produces stainless steel products that are suitable for cold working conditions necessary with screws and nails.

硅

硅的添加提高了不锈钢对高浓度的硝酸和硫酸的抗性。它还促使铁素体的形成,并使金属抗氧化具有抗性。

Nitrogen

Nitrogen is an austenite stabiliser and it improves the strength and localised corrosion resistance. Localised corrosion refers to phenomena such as pitting corrosion, crevice corrosion, and inter-granular corrosion.

钼

钼和钨提高一般localised corrosion resistance properties. The former is a ferrite stabiliser and hence, when used in austenitic alloys, must be balanced with austenite stabilisers to maintain austenite composition.

钼also enhances high-temperature strength when added to martensitic stainless steel. Adding tungsten with molybdenum also improves the above-mentioned properties.

Manganese

Manganese improves the properties of strength, toughness and hardenability in stainless steel. The addition of manganese helps the metal perform better in hot working processes.

Manganese also promotes the solution of nitrogen in stainless steel and may, therefore, be added to replace nickel in stainless steel with nitrogen.

结论

圣ainless steel brings along corrosion and heat resistance besides the conventional properties of steel. It provides all the advantages of steel along with a few of its own. It does not corrode easily, endures rough environments better and has a longer service life.

But it is not completely true that it is stain-proof. Firstly, the resistance to corrosion depends on the grade. However, abnormal surrounding conditions such as low-oxygen, poor circulation and high salinity may stain it irreversibly.

Despite the above risks, stainless steel is a wonder material and has a highly positive impact on the industry as a whole. Due to so many grades with different properties, there is always a grade that is perfect for an application. It is essential to choose the grade wisely to ensure a cost-effective investment.