ASME Y14.52009 GD&T Standards lists out14 types of geometric tolerances. These 14 tolerances are bunched up into five different groups based on the type of control they offer. Among these five groups is runout control.

It is a type of combination control (the other being profile control). Combination controlsaffect more than one feature of a part例如方向,位置,大小和/或表格。

There are two types of runout controls:

- Runout or circular runout

- Total runout

在这篇文章中,我们将了解圆跳动.

What is Circular Runout?

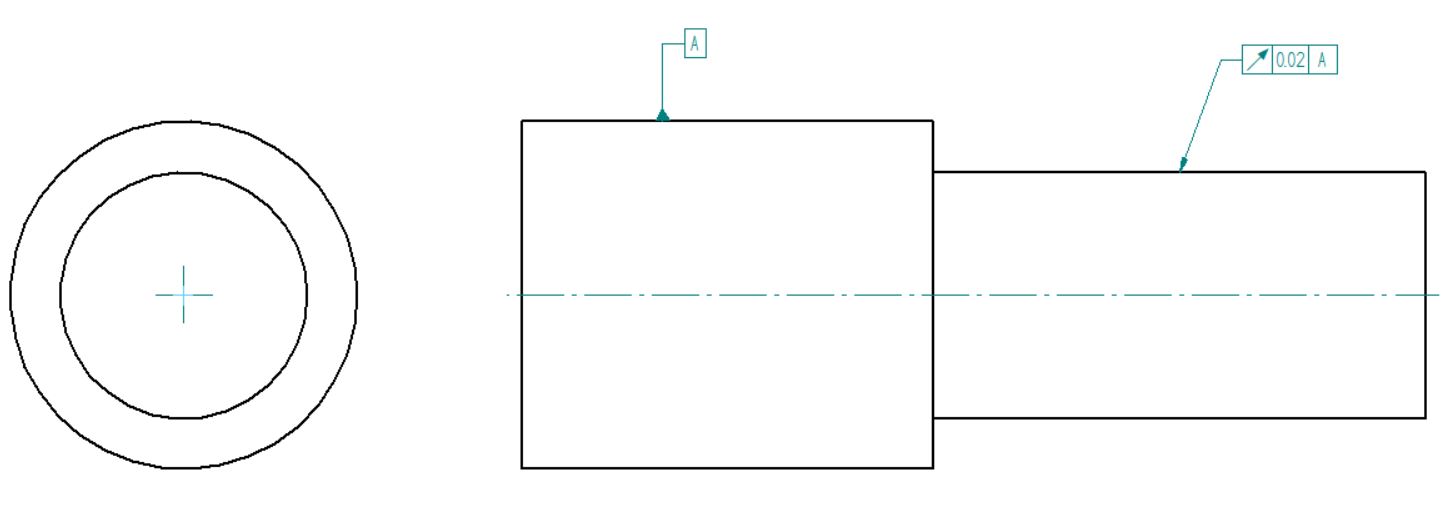

Circular runout, commonly known as just ‘runout’ is a 2D measure of a circular profile in relation to a datum axis. It inspects how well a circular cross-section conforms to a perfect circle much like circularity.

The question then arises: Why do we need another callout to check the circular profile when we already have thecircularity callout?

The circularity callout does check the circularity of a feature, but it does not do so in reference to a datum axis.

So, a surface that is perfectly round would meet the circularity callout even if it is off-centred. This could, however, cause the part to wobble when it rotates during service.

Circular products that require close tolerances or rotate at high speeds must rotate around the central axis besides being as circular as possible to prevent errors in operation. Even a small wobble can significantly affect the functionality and reduce service life.

循环跳动有助于我们控制和测量这种摆动,以确保其在允许的范围内。

The datum axis acts as an anchor for the tolerance zone in circular runout. The callout creates a 2D circular tolerance zone around the specified datum axis. The ideal surface of the feature lies in this tolerance zone. In order to meet this callout, all points on the actual surface must lie in this zone.

Runout manages to specify everything necessary to avoid the wobbling effect不放置许多不同和太紧的公差on the part.

圆形跳动的功能控制框架

功能控制框架遵循与其他GD&T符号相同的规则。圆形跳动框架由三个部分组成。

Circular Runout Symbol

The runout symbol is a diagonal arrow pointing northeast (↗)。这是我们如何测量功能的跳动的引用。我们使用表盘或高度计来测量跳动,因此该符号实际上代表了拨号表中的指针。

跳动符号放置在功能控制框架的第一个隔间中。

公差极限

The tolerance limit makes up the feature tolerance compartment (2nd block) of the feature control frame. Note that the circular runout callout does not need the diameter symbol in the feature tolerance block.

The total variation on the dial gauge must be less than the stated limit.

Datum axis

与GD&T通常情况一样,这是Rughout FCF中最重要的部分。通常,我们选择中央轴作为主要基准,并在第三个块中提及。但是在某些情况下,我们可以选择不同的轴作为基准。

Sometimes, the primary datum is the surface of the circular feature. Other times, it may be the plane perpendicular to the central axis.

在极少数情况下,可以将两个基准组合在一起并用作主要基准,而不是一个基本数据,而另一个是次要数据。

Get your manufacturing quote in seconds

引用几秒钟

Short lead times

Delivery by Fractory

如何测量循环跳动?

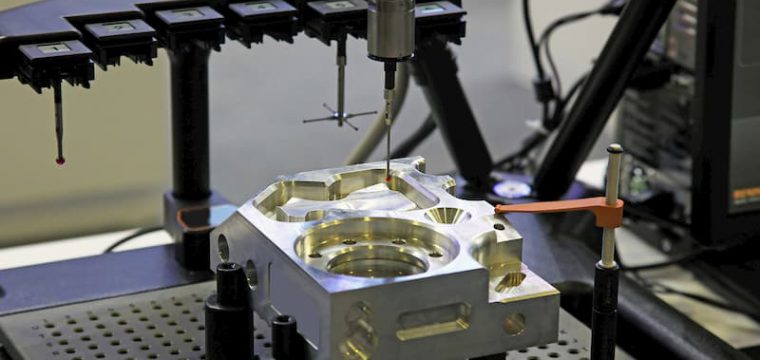

使用简单的高度或拨号仪测量跳动。我们通过沿其基准轴的V块或主轴固定零件。然后将拨号量规的引脚设置在圆形特征上,并将表盘设置为零。

We now rotate theCNC machinedpart along the spindle and record the measurements. The total variation on the height gauge must not exceed the tolerance limit in the feature control frame.

我们可以测量平行,角度或垂直于轴的表面的跳动。在所有情况下,我们保持垂直于表面的高度计。对于每种情况,沿高度销钉的方向创建了一个二维公差区。然后,测试了必要的许多横截面。

For surfaces that are perpendicular to the datum axis, we are testing flatness rather than circularity when we use this callout.

When using it for angled surfaces, we must remember to mention the basic angle, so we can set the height gauge exactly perpendicular to the surface.

用例

如前所述,我们使用圆形跳动进行旋转零件,以防止最终组件中的任何摆动。此类零件的示例包括钻头,车轴,齿轮,轴等。确定跳动是否会在零件上有效,我们设定的标准如下。

There are three types of parts that circular runout can control effectively. If the parts have one of the following three features, we use total runout control or we opt for something more appropriate.

Parts with a high length-to-diameter ratio

具有这种配置文件(例如金属管)的零件可以轻松地将其固定在适当的位置并旋转以检查配置文件。

Sufficient length is critical in ensuring the degrees of freedom (DoF) are restricted as needed for an accurate inspection. This is the ideal part for which runout is most effective.

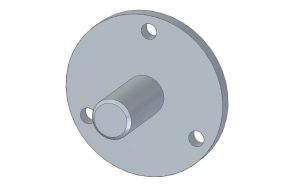

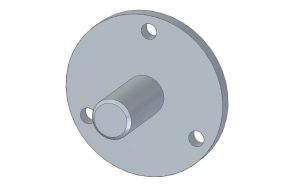

Parts with a small diameter and a perpendicular plane

In case the part has a short length and small diameter but is accompanied by a perpendicular plane (a flange for instance), circular runout can help us inspect the accuracy of the part.

In such a case, we cannot use the central axis as the primary datum as it will not be able to effectively constrain the required degrees of freedom for inspection.

So we set the perpendicular plane as the primary datum and the central axis as a secondary datum. Such parts are held with an expanding chuck to rotate the part.

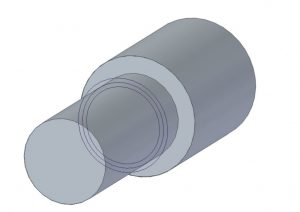

Parts with multiple small diameters far apart from each other

An example of such a part is a concentric pipe reducer. In such a part, there are multiple short diameters at the extreme ends of the part. Both the datum axes are combined and used as the primary datum instead of one being used as a primary and the other as a secondary datum.

例如,如果A和B是零件末端的短轴,则可以通过将基准块中的A和B组合为| A-B |来同时使用它们来检查其他中心部分特征。

Why Use Circular Runout?

如前所述,圆形跳动是一个组合控制,确定了零件特征的组合。使用圆形跳动,我们可以在二维中控制位置,方向和形成。

An exception occurs when the size tolerance is stricter than runout tolerance. In such a case, size tolerance controls the form of the feature. Using just this one callout, we can control the following physical characteristics.

Circularity

The callout controls the circularity of the inspected cross-section. We can inspect the circularity of the entire product by selecting multiple cross-sections since runout is a 2D callout and can focus on only one cross-section at a time.

Coaxiality

由于Chuck持有的部分以及对特征沿相同轴旋转的旋转,因此跳动还控制了这两个功能的同轴性。这间接确保所有检查的特征都是彼此同轴的。

Concentricity

Runout can also measure concentricity for a product.ASME Y14.5当至少三对直径相对点的中值位于中央轴上以进行考虑的横截面时,将零件定义为同心。

The concentricity of a cross-section is the smallest circle around the central axis within which all the medians of all diametrically opposed points of a cross-section lie.

在跳动特征的情况下,所有表面点都位于狭窄的圆形公差区域内。结果,所考虑的横截面的任何一对直径相对点的中值也位于中央轴周围的狭窄区域内。

实际上,跳动不仅比较截然相反的点。它比较了表面的极端变化,并将其保持在公差极限之下。因此,从某种意义上说,跳动是一种更好的同心度量,机械师通常会将其用作同心的理智检查。

Derived median line (DML) straightness

如果我们将上述同心检查扩展到产品的长度上,我们将获得所有横截面中位数形成的线。这是因为所有横截面均沿着相同的中央轴为中心。

因此,当延长整个长度时,此标注还控制着straightnessof the derived median line.

平坦

跳动还控制着垂直于我们的主要基准的功能的平坦度。这是因为我们通过将量规引脚垂直于平行于基准轴平行于环形环表面来测量平面。

So any deviations on the dial gauge will be indicative of surface irregularities. Fewer deviations on the dial gauge represent a flatter surface.

All the above-mentioned characteristics are important features of a product to ensure proper assembly and function. It is possible to use different callouts to check each of the features. But it does not make sense to use these many callouts on our drawings. Each separate callout would also bring into play its own inspection method.

我们通过使用循环跳动来避免这种情况以及其检查方法,以确保仅通过一个标注将上述所有功能保留在允许的限制内。

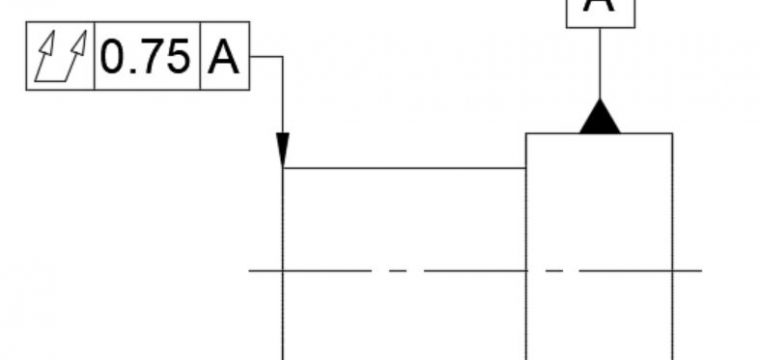

Circular Runout vs Total Runout

In simple terms,total runout3 d相当于圆跳动。而背景cular runout forms a circular tolerance zone around the surface (2D), total runout forms a cylindrical zone.

Besides placing tolerance limits on a cross-section, total runout places it along the entire cylindrical surface to control all cross-sections of the considered feature at the same time. Thus, it accounts for axial variations along with cross-sectional variations.

Total runout helps us control more characteristics than circular runout. It is capable of controlling surface characteristics such as:

- Circularity

- Coaxiality

- Concentricity

- Straightness

- Cylindricity

- 锥度

- 并行性

- Angularity

- Perpendicularity

- Profile

总跳动的检查过程也更为复杂。与圆形跳动类似,我们使用高度计检查总跳动。

在循环跳动中,我们沿指定的基准旋转零件,并记录高度量规上的更改。

In addition to rotating the part, we move the height gauge along the datum axis to measure axial deviations in total runout. If the gauge readings do not vary more than the total runout tolerance, the part is in spec.

In many cases, a CMM inspects the total runout of a part for accuracy.

Total runout is not used as commonly as circular runout as it puts a lot more restrictions on surface characteristics. But it still finds usage especially for products demanding high accuracy and/or rotating at high rpm. Examples include pump shafts and automobile transmissions.

Important Points to Remember

- 与圆形不同,圆形跳动需要基准。因此,请记住提及您的标注中的基准。

- Circular runout is always understood as a 360° rotation around the datum axis and hence, is used without a diameter symbol in the feature control frame.

- Runout is a surface control and not a feature of size control. As such, it is always called RFS (Regardless of Feature Size). Material condition modifiers or bonus tolerances are not used with circular runout.

结论

Runout is a widely used symbol to ensure our products mate well and function as needed. It controls many surface characteristics while being easy to inspect. In fact, it is easier to inspect than certain other callouts that are not even as versatile, e.g. concentricity.

This post would be incomplete without us using the famous quote about runout, “When in doubt, use runout.”